At FCS Finland Oy, we believe airplanes are built to fly and not sit on the ground. We are committed to design and build devices and equipment to minimize the maintenance downtime.

Our products are built using the best components and materials available to ensure reliability and quality of the highest standard.

FCS Finland is located in Turku, Finland, where also our manufacturing and assembly happens.

Our products are already being used by the following airlines all around the world:

Qantas airways, Air New Zealand, Helvetic Airways, Etihad airways, Lufthansa, Air France, Delta Airlines, Vueling, Finnair

Our products

AFC-22

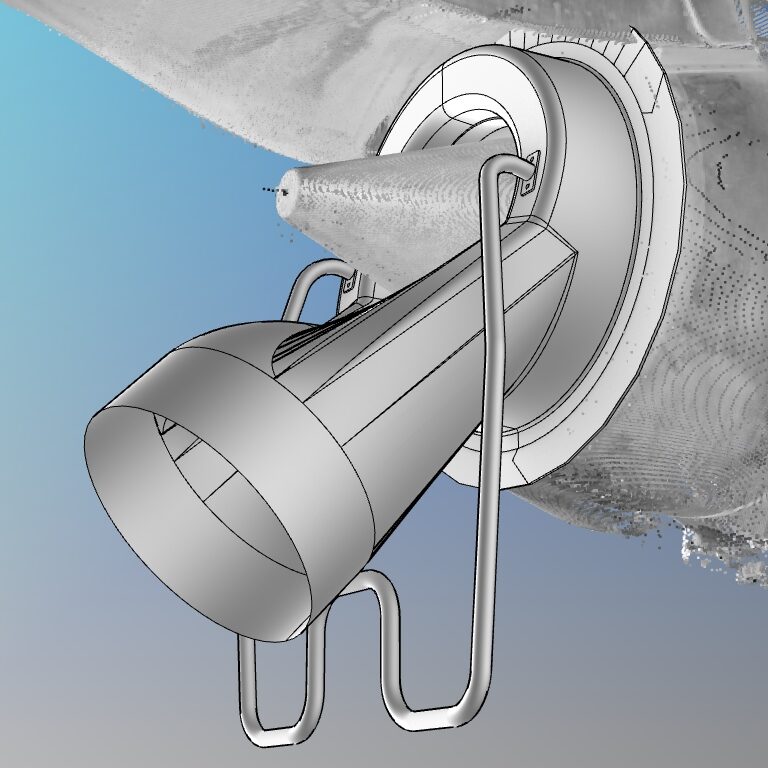

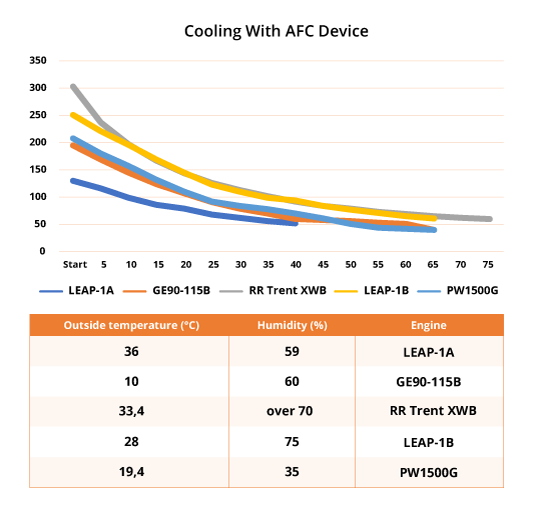

Our patented product is AFC-22, that is a professional cooling system for aircraft engines. AFC-22 uses non-mechanical vacuum based system for engine attachment and cools down the engine in fraction of the time typically needed. Custom fit nozzles are available for different engine types. AFC-22 enables fast and efficient engine maintenance for our customers and minimizes the aircraft downtime.

AFC-23

AFC-23 Hybrid pushes the infrastructure limits away. Compared to AFC-22, it can be also used without an external power. It has an integrated generator powered by a gasoline or diesel driven engine. As an alternative method also, an external power can be used. AFC-23 Hybrid was designed based on the feedback given by our customers. In addition to its integrated generator, it has a sturdier undercarriage, improved tow capabilities, and a slimline profile. Now jet engine cooling can be easily performed either at apron or in hangar.

Custom fit

The nozzles are always custom fit for the specific engine type and model. We ensure thus the perfect fit between the nozzle and the engine, granting a stress free use of the AFC-22 and AFC-23.

Less downtime

The AFC-22 and AFC-23 cut the cooling down time of an aircraft engine to it’s fraction. Our customers can make huge cost savings and optimize their fleet with the AFC-22 and AFC-23 cooling as a standard maintenance process.

Engine types

Currently we have adapters available for following jet engine models:

• Rolls-Royce Trent XWB -84

• Rolls-Royce Trent 7000

• Rolls-Royce Trent 1000

• Rolls-Royce Trent 900

• Rolls-Royce Trent 800

• CFM International CFM56-5B

• CFM International CFM56-7B

• CFM International Leap 1A

• CFM International Leap 1B

• General Electric CF6-80E1

• General Electric GE-90 115B

• General Electric GE-90 94B

• General Electric GEnx-1B

• General Electric GE9X

• International Aero Engines V2500

• Pratt & Whitney 1100G

• Pratt & Whitney 1500G

• Pratt & Whitney 1900G

Please contact us for more details.

Specifications

AFC-22

* = RR Trent XWB Adapter

AFC-23

Contact

FCS Finland Oy

Juhana Herttuan puistokatu 21

Auriga Business Center

FI – 20100 Turku, FINLAND

tel. +358 40 7230555

Kimmo Hotanen

CEO, Sales & Customer Care

tel. +358 40 7230555

Our agents in the USA, Europe, Middle East, South/ Southeast Pacific and Latin America.

Please contact:

Technical Support: